Metals USA excels in all aspects of steel plate processing, and employs both traditional processing techniques, as well as the most advanced CNC (computer numeric controlled) equipment, providing the most efficient and precise steel plate processing currently available. CNC technology has revolutionized the fabrication industry, automating most machining tasks, speeding up production, and offering a higher level of precision. The full range of steel and metal plate processing services are available including drilling, milling, scribing, bending, beveling, rolling, shearing, tapping, countersunk/counterbored holes, and much more. Advanced cutting methods are also available, including CNC laser, oxy-fuel, and plasma burn technology. Formed parts, including heavy steel plate forming, manufactured parts, plate duplicating, and other types of advanced steel plate processing are all part of Metals USA’s skill set. Utilizing these services customers save time and money while receiving high quality parts for numerous applications.

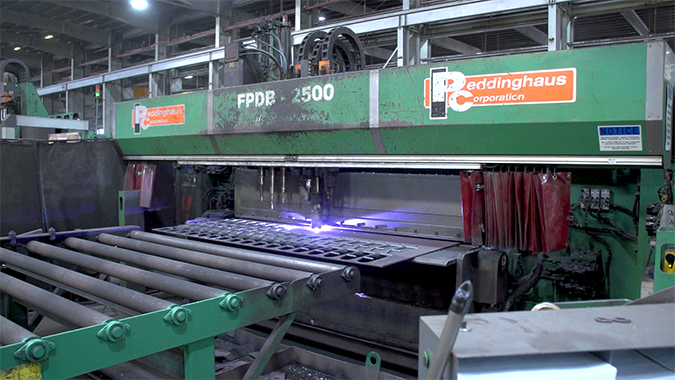

- Plate Burning

Plasma/Oxyacetylene

Heavy Plate Burning – Up to 17” thick

Laser - Part Duplication Services

Drilling

Countersinking

Counterboring

Tapping

Milling

Beveling

Scribing - Plate Shearing

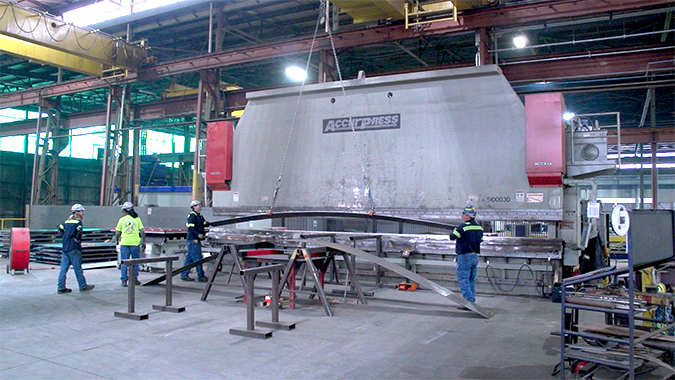

- Plate Forming

Bending

Radius Rolling

Bump Pressing

Forming - Part Cleaning and Packaging

- Blasting and Painting

- Heat Treating